Send inquiry

Ultrasonic liquid level switch can be used in a wide range of applications, without any calibration or set, which is one of the most economical and effective solution for you!

Basic Info

- Type: Ultrasonic

- Output Signal Type: Switching Type

- Feature: Corrosion Resistant

- Protection Class: IP66

- Customized: Customized

- Power Supply: 220VAC+-15%, 24VDC

- Scale: 0-6 m (or to be customized)

- Resolution: ±2mm

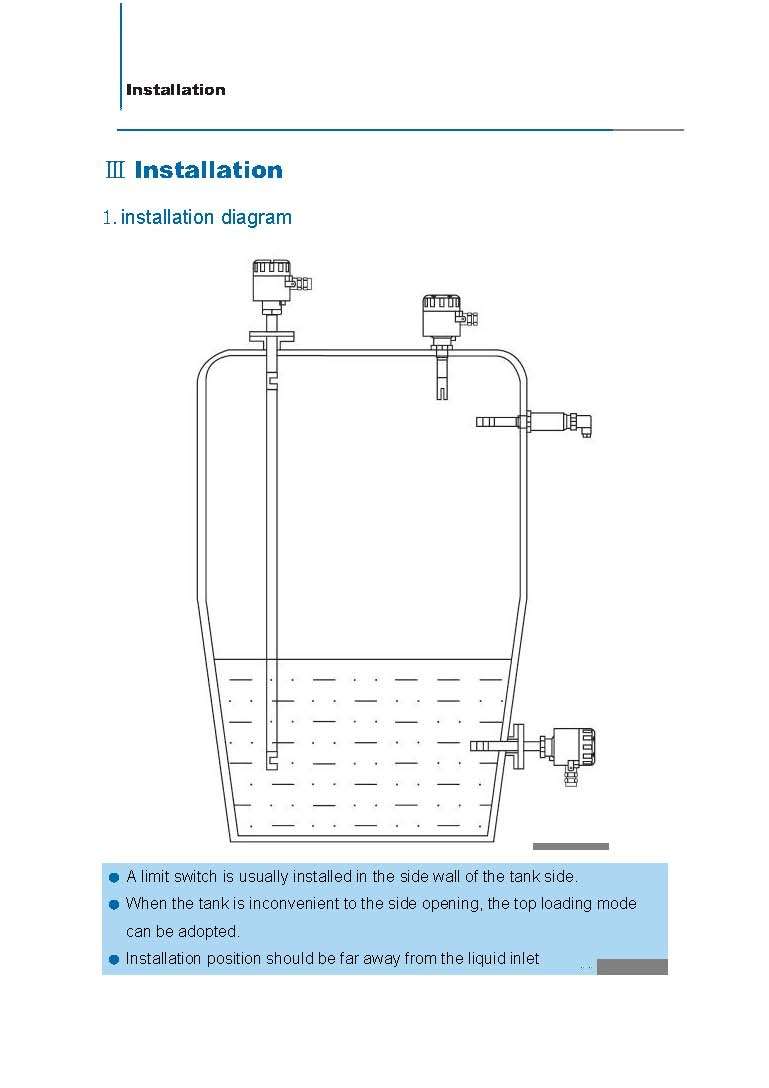

- Installation Type: Top / Side Mounting, Flange or Thread

-

Origin: Huai'an, Jiangsu, China

Ultrasonic switch is a kind of high frequency sound(ultrasonic) that can be used to check whether there is liquid in the specified location. The instrument is composed of an electronic control device and a probe.

Ultrasonic Liquid Level Switch uses ultrasonic wave's different propagation characteristics in air and liquid to detect the liquid level of the liquid, which is when the sound wave propagates in the air, the signal intensity appears very big loss, while in the

liquid, the signal intensity almost remains unchanged.

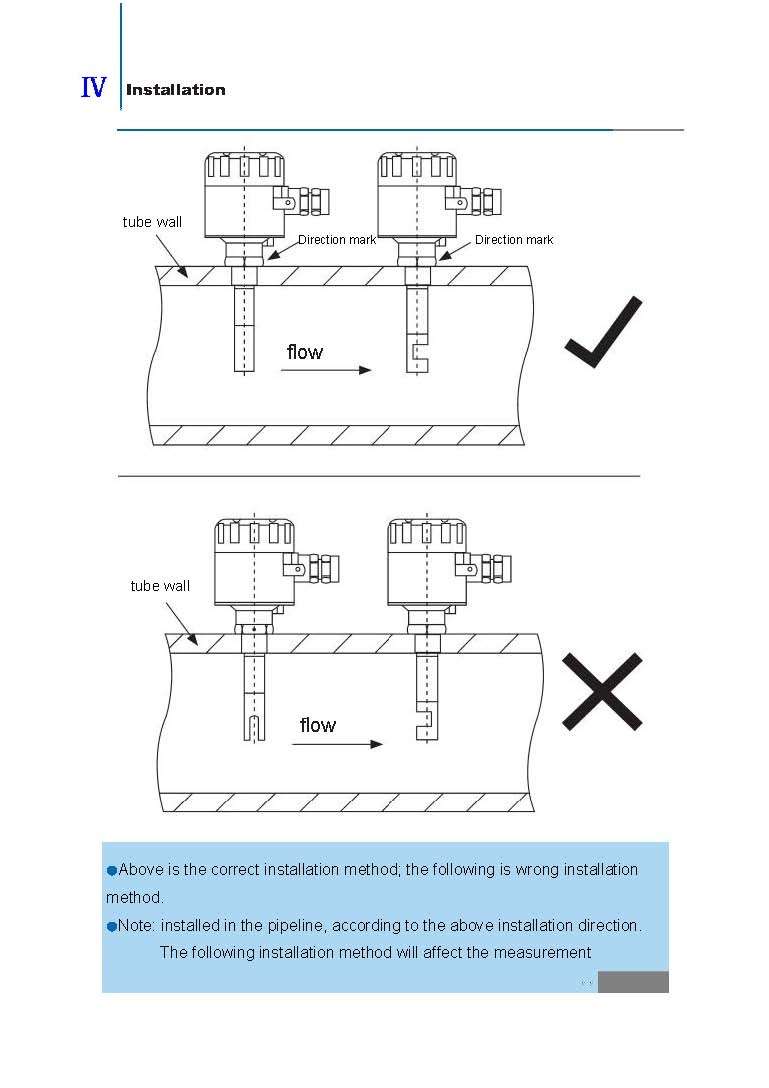

In order to achieve the purpose of detecting the liquid level, we have to determine whether there is a liquid or a gas (air) in the recess. Because the liquid density is higher than that of the gas, it is easier to spread the sound wave through the liquid. The first

sensor transmits sound wave at one side of the groove, and second sensor on the other side detects the sound wave. When the liquid is in the groove, the sound wave received by the detection side is very large. When the gas (air) exists in the groove, the detection side can only receive a small amount of sound wave. The electronic circuit can detect the difference of the acoustic wave quantity and then output relay switch signal correspondingly.

The Ultrasonic Liquid Level Switch includes two piezoelectric crystal, one for acoustic emission, and the other acts as an receiver. These two piezoelectric crystals are respectively arranged on both sides of the groove metal sensor.

-